INSTRUCTIONAL

DESIGN EXAMPLE:

5S LEAN Manufacturing

Course

Welcome to the 5S Lean Manufacturing Course. I created this to capture the Instruction Design (ID) process that went into creating this course to achieve stakeholder approval.

This site provides examples of the following ID process steps:

-

Needs & Audience Analysis

-

Goals & Objectives

-

Assessments & Evaluations

-

Content Outline

NEEDS & TASK ANALYSIS

Overview

Manufacturing industries are constantly looking for ways to increase productivity to meet market demands. A focus on continuous improvement efforts to increase efficiency, reliability, and optimization of business processes and procedures through the elimination of production waste are their primary goals in achieving this (Chandrayan et al., 2019). In turn, many manufacturing industries have implemented 5S Lean manufacturing principles and practices into their company to help them do this. 5S Lean is a housekeeping technique created by Hiroyuki Hirano in Japan in the 1950s, used to improve the Toyota production system and now a proven tool used by manufacturing industries throughout the world to reduce production waste (Al-Aomar, 2011; Chandrayan et al., 2019).

Lean manufacturing focuses on the elimination of eight types of production waste which include:

-

Overproduction – Manufacturing a larger than needed quantity before it’s required.

-

Waiting Time – Delays in production due to unavailable workers and/or unusable machinery.

-

Transportation – Amount of time to move materials, parts, labor, etc.

-

Overprocessing – Using over skilled labor to do the work less skilled workers can do.

-

Inventory – Accumulation of stock materials, products, parts, tools, etc.

-

Defects – Poor quality work leading to scrapped materials or products, repair, rework, and re-inspections causing production delays.

-

Motion – Excess movement in the production process by workers.

-

Underutilized Resources – Unused space, machines, personnel, etc. (Al-Aomar, 2011).

5S Lean, derived from five Japanese words consists of:

-

Seiri (Sort) – Removing unneeded items not required to perform a task or job from needed items to make the area clutter-free.

-

Seiton (Set in Order) – Organizing, straightening, and labeling needed items to make them easier to locate and find.

-

Seiso (Shine) – Cleaning the area to ensure a safe and clean working environment.

-

Seiketsu (Standardize) – Creating processes, procedures, checklist, etc., to ensure standardization and continued use of implemented improvements.

-

Shitsuke (Sustain) – Conducting training and audits on a regular basis to ensure newly implemented processes and procedures are being practiced and followed (Chandrayan et al., 2019).

Each of these five steps is used for ensuring an organized, clean, and safe working environment to drive the elimination of production waste.

Problem Statement

With an increase in retiring skilled manufacturing workers, it is difficult to find skilled entry-level workers to fill these positions. Selko (2021) stated that 54% of manufacturers are struggling to find skilled workers to replace their aging workforce. Per Anid (2018), manufacturing industries will need to hire 3.5 million new employees to replace the aging skilled workforce over the next 10 years. Unfortunately, most new hires have little to no knowledge of 5S Lean manufacturing, leading to an increase in production waste due to safety and quality issues and costly delays in production.

One key issue seen in the industry is an increase in foreign object debris/damage (FOD) which Rizkya et al., (2019, p. 1) describes as “any little thing, molecule, or garbage that doesn’t have a place” and does not belong in the work area or finished product such as tools and trash left behind after production. FOD costs the aerospace industry over $4 billion (US) dollars every year and has even been associated with aircraft catastrophic failures/disasters such as Air France Flight 4590 that crashed July 25, 2000, during take-off due to metal FOD on the runway, causing the deaths of 113 people (Rizkya et al., 2019). In turn, this is why manufacturing industry leaders, workforce development representatives, and industry customers have identified 5S Lean as a skill gap that needs to be implemented into high school entry-level Career and Technical Education (CTE) programs such as Core Plus Aerospace (CPA) in Washington state.

Instructional Design Needs Analysis

To determine if 5S Lean skill gaps existed, previous data was utilized that had been collected over the past two years by Workforce Development representatives within the industry and a needs analysis was conducted utilizing Mager’s Performance Analysis Flowchart (see Appendix A) to determine if a formal training program should be designed to bridge the skill gaps (Brown & Green, 2020).

Internal Data Collection – Industry Hiring Requirements

Internal data captured 5S Lean competencies hiring requirements through the help of industry subject matter experts (SMEs) (see Appendix B). It included a Likert scale from 0-6, with 0 equating to no experience required and 6 equating to expert level requirement as well as a criticality level ranging from low to critical. SMEs identified both Lean manufacturing and 5S entry-level hiring requirements levels equated to a 3, meaning students should be able to apply 5S Lean practices and process with minimal supervision. SMEs also assigned these as critical skills which means new hires must possess these skills in order to be hired into entry level positions.

External Data Collection – Academic Program Skill Gaps

Data captured from the 52 CPA school programs included an emailed Skill Competency Assessment form (see Appendix C) used to determine alignment to the internal hiring requirements. Average score calculated showed instructors had no understanding of 5S Lean and did not possess the knowledge or skills on the topic. Lastly, an in-person Program Assessment (see Appendix D) and in-person Instructor Interview (see Appendix E) were each conducted by industry Workforce Development representatives. The assessment showed programs practiced little to no 5S Lean principles or practices. Most classrooms were cluttered, no FOD control visible, and there was a high level of production waste taking place in the classrooms. Instructor interviews showed the majority of instructors possessed no formal 5S Lean training.

Conclusion

Internal and external data captured from the needs analysis exposed 5S Lean skill gaps. The data showed the majority of the 52 Core Plus Aerospace CTE program instructors possessed no formal training which supported Mager’s Performance Analysis results that instructional design (ID) is needed to create a 5S Lean course to ensure instructors understand what 5S Lean is, the importance of practicing it and implementing it into their high school classrooms and curriculum (Brown & Green, 2020). Real-world, experiential learning activities are needed as well as activities that can be used in the CPA instructors’ classrooms so they can pass these skills down to their students. Many of these activities already exist internally within the industry and through various websites which makes this a low-cost solution as training for teachers could take place in industry and shared externally to be used in the classroom curriculum. In turn, this course will drive to the primary goal of industry and manufacturing customers to ensure CPA high school graduates have the skills required to be hired into entry-level positions in manufacturing and drive 5S Lean culture within the future workforce.

AUDIENCE ANALYSIS

Overview

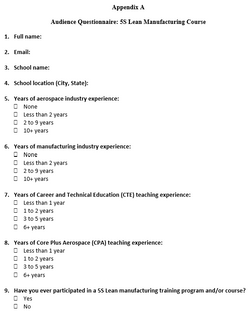

This audience analysis aims to provide insight into the design of a new course on 5S Lean Manufacturing for high school instructors in Career and Technical Education (CTE) programs, specifically those teaching the Core Plus Aerospace (CPA) curriculum in Washington state. The analysis is based on the responses gathered from a Microsoft Forms assessment questionnaire (see Appendix A) administered to a carefully selected group of 20 instructors.

Audience Selection and Questionnaire Process

The comprehensive questionnaire aimed at gathering diverse information about the audience. This included contact details, geographic location, industry experience, CTE and CPA teaching experience, 5S Lean educational background and experience, instructor interest in the proposed course, and concerns regarding the integration of course content and practices into their classrooms.

On February 15, 2024, instructors were contacted via mail (see Appendix B) and requested to provide consent for participation in the Microsoft Forms assessment questionnaire, with the form link embedded in the email. The questionnaire, requiring approximately 10 minutes to complete, comprised of 16 questions (see Appendix A). Responses were expected by February 25, 2024, and additional outreach via email and phone calls was conducted until February 28, 2024, for schools that had not responded by the original due date. Among the 20 high school instructors contacted, 15 responded to the assessment questionnaire, and the detailed results are outlined in Appendix C. To preserve participant confidentiality, responses to questions one through three have not been disclosed.

Certain demographic data, such as gender and age range, were not included in the assessment questionnaire, as this information had been previously captured. Notably, out of the 20 instructors surveyed, only 10% were female, and the age range of the population spanned from 29 to 65 years old. This intentional selection and meticulous data collection process aimed to ensure a diverse and representative sample for the audience analysis.

Rational for Assessment Questions

The rationale behind incorporating the specific questions (see Appendix A) into the audience analysis assessment questionnaire is multifaceted. The questions were meticulously designed to gather essential information about the instructors, enabling a personalized and tailored course development process.

Audience Contact Information – Questions 1 – 4

Collecting full names and email addresses establishes a personal connection, aiding in effective communication and ensuring accurate identification throughout the course. Information on school names and locations provides context about the educational institutions, facilitating customization of the course content to align with specific school environments and regional considerations.

Industry, CTE, & CPA Experience – Questions 5 – 8

Questions regarding aerospace and manufacturing industry experience, as well as CTE and CPA teaching experience, help tailor the course to align with the instructors' expertise and pedagogical approaches. Understanding the years of experience in each of these areas ensures that the training is relevant, applicable, and resonates with their real-world experiences (Barkley & Howell, 2016). Also, understanding instructor exposure to an industry environment is critical for them to make connections to 5S Lean practices in a real-world environment and how these relate in a classroom as well (Kolb & Kolb, 2017).

5S Lean Background and Experience – Questions 9 – 11 & 13

Specific inquiries about prior 5S Lean training, familiarity with 5S Lean manufacturing principles, and teaching experiences with 5S Lean help assess the baseline knowledge of instructors, ensuring that the course content is appropriately targeted to address specific knowledge gaps and avoid redundancy.

The frequency of integrating hands-on 5S Lean activities into teaching methods is assessed to seamlessly incorporate such activities into existing practices. Inquiring about openness to ongoing professional development expresses instructor motivation to learn the content and ensures a commitment to continuous improvement, contributing to the long-term success of the course.

5S Lean Classroom Implementation and Industry Partnership – Questions 12 & 14 – 16

Lastly, questions about industry partnerships and collaboration experiences inform the incorporation of real-world insights into the curriculum, enriching the course content. Identifying preferred resources and anticipating challenges in implementing 5S Lean principles helps tailor the course to the specific needs and preferences of the instructors. This comprehensive approach ensures that the course design addresses individual concerns, provides targeted solutions, and creates an effective and engaging learning experience for the participants.

Reflection

The diverse responses from the audience analysis questionnaire provide valuable insights that will significantly shape the design of the 5S Lean Manufacturing course.

Geographical Audience and Teaching Experience

The spread of school locations across Washington state (Port Orchard, Bremerton, Vancouver, Olympia, Elma, Tacoma, Sumner, Seattle, Everett, Renton, Anacortes, Marysville, Yakima, Spokane, and Walla Walla) highlights the need for regional considerations in the course content. Understanding the varied years of aerospace (Figure 1) and manufacturing (Figure 2) industry experience, along with CTE (Figure 3) and CPA (Figure 4) teaching experience, allows for tailoring the course to accommodate the different levels of expertise within the group.

5S Lean Experience and Course Interest

The fact that a majority of the instructors have not participated in a 5S Lean training program (Figure 5) indicates the necessity of a course that caters to both beginners and those with some familiarity. The varying degrees of familiarity with 5S Lean principles (Figure 6) suggest the need for a curriculum that offers comprehensive coverage, catering to both the novices and those with some prior knowledge. Their experiences with teaching 5S Lean manufacturing (Figure 7) and industry partnerships (Figure 8) reveal the diverse background of the group, emphasizing the importance of creating a course that can leverage their varied experiences for mutual learning.

Understanding the instructors' current practices in terms of integrating hands-on 5S Lean activities into teaching methods (Figure 9) provides an opportunity to align the course with existing practices, making it more seamlessly integrated into their curriculum. The high openness to ongoing professional development (Figure 10), especially when CTE clock-hours are provided, signifies a positive attitude towards continuous improvement and creates a conducive environment for engaging, long-term learning.

Implementation of 5S Lean Principles

The identified resources and support preferences, including lesson plans, classroom activities, and training workshops, along with specific requests for industry help and guidance as well as a classroom visit with an industry expert for implementation guidance, inform the creation of a resource-rich curriculum (Figure 11). The specified challenges and difficulties, such as lack of resources, funding, resistance from students, and limited time in the curriculum, underscore the importance of addressing practical constraints (Figure 12). Furthermore, challenges like CTE Director approval and buy-in from school administration indicate the need for strategies to garner institutional support for successful course implementation (Figure 12).

Conclusion

The audience analysis findings from the 5S Lean Manufacturing course for high school instructors in Washington state's Core Plus Aerospace (CPA) program highlight the necessity for a flexible and regionally adaptable curriculum. With a diverse group of instructors across different locations and varying levels of industry and teaching experience, the course design must be comprehensive and cater to both beginners and those with some familiarity with 5S Lean principles. The openness to ongoing professional development signals a positive attitude toward continuous improvement, setting the stage for engaging, long-term learning. These insights emphasize the importance of creating a resource-rich curriculum that addresses practical constraints faced by instructors, such as limited resources, funding, and time.

Future assessments should delve deeper into institutional support strategies, focusing on obtaining CTE Director approval and garnering buy-in from school administration to ensure the successful implementation of the course in high school CPA classrooms. Also focusing on considering Maslow’s Hierarchy of Needs to capture instructor physical, emotional, mental, and spiritual health as well as their preferred learning style(s) (Brown & Green, 2020). Looking back at Brown & Green’s (2020) chapter on Learner Analysis, I’m reminded of pulling in more of Robert Mager’s recommendations, page 89, to help make the assessment more detailed and robust. Overall, the analysis provides a solid foundation for tailoring the course to instructors' specific needs and preferences, ensuring an effective and engaging learning experience.

Appendix: Audience Analysis

|  |  |

|---|

GOALS & OBJECTIVES

Overview

The pressing need to bridge skill gaps in high school Career and Technical Education (CTE), specifically Core Plus Aerospace (CPA) programs in Washington state, underscores the significance of targeted professional development. With an increasing demand for skilled manufacturing workers, this paper explores the goals and objectives of a comprehensive 5S Lean Manufacturing training course designed for CPA high school instructors. The course aims to empower educators with the knowledge and practical skills necessary to integrate 5S Lean principles into their classrooms, ultimately contributing to the development of a future workforce well-versed in efficient manufacturing practices.

The development of learning goals and objectives for this course combines Bloom’s taxonomy with Robert Mager's performance-based approach (Brown & Green, 2020). Mager’s methodology underscores performance objectives intricately linked to observable behaviors and revolves around three essential components: (1) the "Action" the learner will take upon achieving the objective, (2) the "Condition" specifying the circumstances under which the learner will act, and (3) the "Criterion" outlining the level of proficiency required for the learner to successfully perform the action (Brown & Green, 2020).

First Goal and Aligning Objectives

The primary goal of the training course is to equip high school instructors with the expertise to seamlessly integrate 5S Lean manufacturing principles into the CPA curriculum. First, participants will demonstrate proficiency in the application of 5S Lean principles, as evidenced by a visible reduction in clutter and production waste within their classroom environments. Second, participants will incorporate hands-on 5S Lean activities into their teaching methods, aligning these activities with existing instructional approaches. Lastly, participants will develop a comprehensive action plan outlining strategies for sustaining 5S Lean practices in their classrooms, including regular audits and integration into the curriculum, with the aim of fostering a lasting culture of continuous improvement.

Second Goal and Aligning Objectives

The secondary goal focuses on fostering collaboration between high school instructors and industry partners to enhance the practical application of 5S Lean principles. Participants will establish meaningful industry partnerships, leading to collaborative projects that integrate real-world 5S Lean practices into classroom activities. Through facilitated discussions and workshops, participants will identify and address common challenges in implementing 5S Lean principles, resulting in actionable strategies to overcome barriers. Additionally, participants will conduct classroom visits with industry experts to receive guidance on effective 5S Lean integration, ultimately increasing instructor confidence in incorporating industry-relevant practices into their curriculum.

Conclusion

In conclusion, this paper outlines the imperative goals and corresponding objectives of a tailored 5S Lean Manufacturing training course for high school instructors in the Core Plus Aerospace program (Brown & Green, 2020). By addressing the identified skill gaps, fostering collaboration between educators and industry partners, and providing practical tools for effective implementation, this course seeks to empower instructors and, consequently, enhance the preparedness of students for entry-level positions in the manufacturing sector. The outcomes of this training program are anticipated to contribute significantly to the cultivation of a skilled and knowledgeable workforce capable of meeting the evolving demands of the manufacturing industry.

ASSESSMENTS

Overview

This delves into the integration of learning assessments within a specialized course tailored for high school Career and Technical Education (CTE) instructors, particularly those teaching the Core Plus Aerospace (CPA) curriculum with a focus on 5S Lean manufacturing principles. The objectives of this course revolve around curriculum integration and fostering collaboration with industry partners. To achieve these goals, specific objectives are outlined, each paired with diverse Learning Assessment Techniques (LATs) utilizing Barkley & Major's (2016) recommended assessment method selection guidelines. The selection of assessment methods aims to facilitate the seamless integration of 5S Lean principles into high school CTE classrooms while nurturing collaboration between educators and industry stakeholders.

Primary Course Goal

The primary objective is to equip high school CTE instructors with the expertise to seamlessly integrate 5S Lean manufacturing principles into the CPA curriculum. To assess progress towards this goal, three objectives are identified and matched with appropriate assessment methods.

Primary Goal: Assessment for the First Objective

The first objective is to evaluate participants' proficiency in applying 5S Lean principles to reduce clutter and waste in classroom settings. This is achieved through the Prediction/Anticipation Guide LAT method (Barkley & Major, 2016). Prior to engaging in activities related to 5S Lean principles, participants will answer a series of questions designed to stimulate predictions about outcomes and strategies for decluttering and waste reduction in their classrooms (Barkley & Major, 2016). After the learning activities, participants will revisit their predictions, evaluating their accuracy, and addressing any misconceptions that may have arisen (Barkley & Major, 2016).

This assessment method facilitates active engagement with the material and practical application of understanding, ensuring validity by directly evaluating the implementation of 5S Lean principles, reliability through consistent evaluation criteria, and practicality in administration and analysis. Assessment involves distributing Prediction Guide questions before the learning activities and allowing participants to reflect on their initial predictions afterward, comparing them with actual outcomes.

To assess learners, a form was created using the Anticipation Guide Template (AdLit, 2023) and questions pulled from the course materials (see Appendix A). Participants complete the left-hand “Before” side of the form at the start of the course by filling in an “A” for statements they agree with versus a “D” for statements they disagree with. The forms are collected by the facilitator and held until the end of the course, in which they are handed back to the learners to fill out the right-hand “After” side of the form. The facilitator determines proficiency of the learners in this objective if the students achieve 80% or higher on the final step of the assessment.

Primary Goal: Assessment for the Second Objective

The second objective focuses on assessing participants' ability to integrate hands-on 5S Lean activities into teaching methodologies. This is accomplished using the Sequence Chains LAT method (Barkley & Major, 2016). Participants will graphically depict a sequence of events, actions, roles, or decisions related to incorporating hands-on 5S Lean activities into their instructional approaches (Barkley & Major, 2016).

This assessment method was chosen for its capacity to gauge participants' understanding of sequencing and integrating hands-on activities effectively into teaching methods, ensuring validity by directly evaluating organizational and visualization skills, reliability through clear evaluation criteria, and practicality by facilitating structured yet creative engagement. Participants will submit their visual representations for evaluation, focusing on the logical progression of activities and their alignment with instructional objectives.

To assess learners, the Sequence Chains Worksheet (see Appendix B) will be used. This activity ties in learning from the course materials and assesses if the learners understand 5S Lean principles. Students apply these skills to this hands-on activity in which they list the main steps involved in incorporating the 5S Lean principles into their classrooms through the creation of a graphical diagram, flowchart, or any other visual tool they choose as well as describe and highlight how these align with their instructional and continuous improvement objectives.

The facilitator determines proficiency of the learners in this objective by the following criteria:

-

Organization - Clear and logical arrangement of the sequence of events.

-

Visualization - Effective use of graphical tools to represent the sequence.

-

Alignment - How well the activities integrate with and support the instructional objectives.

-

Creativity - Innovative and practical approaches in applying 5S Lean principles.

Primary Goal: Assessment for the Third Objective

The third objective is to evaluate participants' capability in developing comprehensive action plans for sustaining 5S Lean practices in classrooms, fostering a culture of continuous improvement. This is achieved through the Insights-Resources-Applications (IRAs) LAT method (Barkley & Major, 2016). Participants will undertake a written assignment involving identifying insights into sustaining 5S Lean practices, locating supportive resources, and outlining strategies for integration into their classroom contexts (Barkley & Major, 2016).

This assessment method enables participants to demonstrate their understanding of sustaining 5S Lean practices within their specific classroom environments, ensuring validity by evaluating the development of actionable plans, reliability through clear evaluation criteria, and practicality by engaging participants in real-world scenarios. Assessment involves assigning the IRAs as a written task following instructions on sustaining 5S Lean practices, with participants submitting completed assignments for evaluation.

To assess learners, the IRA Worksheet (see Appendix C) will be used. This activity is designed to help the learners deepen their understanding of the 5S principles and apply them in a practical context (Barkley & Major, 2016). Students apply these skills to this hands-on activity in which they will read "The 5S Methodology" article (Steele, 2020) and watch the embedded YouTube video (Patrick, 2020). Once they complete this task, they answer three questions related to insights, resources, and application. The facilitator determines proficiency of the learners in this objective by the following criteria: completeness to answer questions and ability to correlate their learning of 5S principles and practices to what they've gained from the article and video.

Second Course Goal

The secondary goal is to foster collaboration between high school CTE instructors and industry partners to enhance the practical application of 5S Lean principles. Similarly, three objectives are identified and paired with appropriate assessment methods.

Secondary Goal: Assessment for the First Objective

The first objective is to gauge participants' proficiency in establishing meaningful industry partnerships leading to collaborative projects integrating real-world 5S Lean practices into classroom activities. This is done through the Digital Projects LAT method (Barkley & Major, 2016). Participants will craft digital projects using the Digital Projects Activity Handout (see Appendix D). The learners will showcase their collaborations with industry partners and demonstrate the incorporation of 5S Lean practices into their classroom activities (Barkley & Major, 2016).

This assessment approach enables participants to exhibit their partnerships and the application of 5S Lean principles in a tangible and innovative manner, ensuring validity by directly assessing the integration of industry practices into classroom activities, reliability by furnishing clear evaluation criteria for the digital projects, and practicality by allowing flexibility in presentation styles.

Secondary Goal: Assessment for the Second Objective

The second objective is to evaluate participants' competency in recognizing and tackling common challenges in implementing 5S Lean principles, leading to actionable strategies for overcoming barriers. This is accomplished through the Role Play LAT method (Barkley & Major, 2016). Participants will immerse themselves in simulated scenarios related to implementing 5S Lean principles, assuming roles and addressing common challenges encountered in the process (Barkley & Major, 2016). Learners will be placed into groups of no more than three people and teams will be provided a Role Play Activity Note Card (see Appendix E) with scenarios they must role play. Learns will be visually assessed by the facilitator during the activity and a class discussion will take place afterwards.

This assessment method was selected for its immersive and interactive nature, enabling participants to explore and address real-world challenges effectively, ensuring validity by evaluating the application of knowledge in simulated scenarios, reliability by providing clear criteria for assessing the effectiveness of strategies developed, and practicality by fostering engagement and creativity.

Secondary Goal: Assessment for the Third Objective

The third objective is to assess participants' ability to conduct classroom visits with industry experts for effective guidance on 5S Lean integration, ultimately bolstering instructor confidence in integrating industry-relevant practices into their curriculum. This is achieved through the Peer Problem Review LAT method (Barkley & Major, 2016). Participants will engage in peer-to-peer evaluation of experiences and solutions derived from classroom visits with industry experts (Barkley & Major, 2016). Learners will partner up. Each group will be provided on Peer Problem Review Note Card (see Appendix F) and work through the problem as a team to come up with a solution. Learns will be visually assessed by the facilitator during the activity and a class discussion will take place afterwards.

This assessment method was chosen to promote collaborative learning and reflection, allowing participants to solidify their understanding of effective 5S Lean integration by evaluating real-world problems encountered during visits, ensuring validity by assessing the application of knowledge gained from industry experts, reliability through a structured peer review process, and practicality by fostering active engagement and discussion.

Conclusion

In conclusion, the integration of learning assessments into a 5S Lean Manufacturing Course for high school CTE instructors is vital for ensuring effective curriculum integration and collaboration with industry partners. By employing diverse assessment methods aligned with specific objectives, instructors can effectively evaluate participant understanding, application, and collaboration skills. These assessments emphasize practical application and collaboration, mirroring real-world challenges educators may encounter. Through systematic evaluation, educators can refine instructional practices and contribute to cultivating a workforce equipped with essential skills for industry success.

Appendix: Assessments to Meet Goal One

|  |  |

|---|---|---|

|  |

EVALUATIONS

Overview

The 5S Lean Manufacturing course for high school Career and Technical Education (CTE) instructors, with a specific focus on the Core Plus Aerospace (CPA) program, is structured to integrate 5S Lean principles into teaching practices. It combines theoretical knowledge with practical applications, leading to an observational factory tour. Evaluations, crucial in gauging the course's efficacy, are conducted throughout the program and consist of formative and summative evaluations (Barkley & Major, 2016). Formative evaluations provide real-time feedback after key activities, facilitating continual course enhancement (Chaparro et al., 2021; Differences, 2017). Summative evaluations follow the course completion, gauging the overall effectiveness and informing strategic decisions for future curriculum development (Chaparro et al., 2021; Differences, 2017). Collectively, these evaluations ensure the course not only meets educational objectives but also aligns with industry needs, serving stakeholders such as facilitators, industry partners, and school administrators with valuable insights for decision-making and continuous course improvement.

Formative Evaluation

The formative evaluation conducted midway through the course serves as a critical juncture for assessing the effectiveness of the instructional strategies employed thus far. Taking place after the interactive "Applying 5S Lean Principles and Practices" session and before participants embark on the "Manufacturing Factory Tour," this evaluation captures participants' immediate responses to the course content and activities.

This mid-course checkpoint is characterized by a dual approach: first, facilitated discussions allow for an open and reflective dialogue, where educators can share their experiences, challenges, and insights gained from applying the 5S Lean principles in role-play scenarios. These discussions help identify whether the concepts are being understood and internalized in a manner that educators find meaningful and applicable to their teaching contexts.

Second, the structured online Microsoft Forms questionnaire, outlined in Appendix A, delves into specific aspects of the participants' learning experiences. The questions are designed to assess the depth of understanding, confidence in application, and engagement levels with the course material using a Likert scale to make it easy for learners to complete.

By integrating immediate verbal feedback with quantifiable data from the questionnaire, the formative evaluation provides a comprehensive view of the course's impact in real-time and allows for a classroom discussion of the results. In turn, it ensures that the course is meeting its core objectives of not just imparting knowledge of 5S Lean principles but also equipping educators with the confidence and competence to apply these principles effectively in their instructional practice. The insights obtained from this formative evaluation are pivotal, as they allow for the agile adjustment of the course content and teaching methods to better suit the participants' needs and enhance their learning outcomes.

Summative Evaluations

Summative evaluations critically assess a course's success in reaching its objectives (Chaparro et al., 2021; Differences, 2017). Post-course evaluations quantify the immediate learning outcomes, while follow-up evaluations, such as the one scheduled six months after course completion, evaluate the long-term integration and sustainability of 5S Lean principles in the classroom setting. These evaluations are pivotal in confirming the course's instructional effectiveness and guiding subsequent revisions to the curriculum.

Part 1 – End of Course Summative Evaluation

Immediately following the course's conclusion, an online summative evaluation is conducted to encapsulate the learning experiences of the participants. This evaluation, as detailed in Appendix B, is designed to critically examine the educational outcomes against the course objectives. It includes a series of targeted questions aimed at assessing participants' understanding of the 5S Lean principles, their ability to integrate these principles into their CPA curriculum, and the practicality of these applications in their teaching environment. Questions are designed to draw out reflections on the course content, the effectiveness of the materials and instructional strategies used, and the participants' readiness to engage with industry partners. This evaluation acts as a decisive indicator of the course's immediate effectiveness and its success in preparing educators for real-world applications of the 5S Lean methodology.

Part 2 – Six-Months Post Course Summative Evaluation

The second phase of summative evaluation unfolds six months after the initial training, where the long-term impact of the course is measured. This evaluation, outlined in Appendix C, involves industry SMEs visiting classrooms to observe and assess the enduring integration of 5S Lean principles into teaching practices. The focus is on the visibility of the 5S principles (sort, set in order, shine, standardize, and sustain) in the classroom organization and the changes in classroom management and curriculum content that reflect the 5S Lean methodologies. The questions are structured to elicit responses that reveal whether the principles taught have been woven into the fabric of the teaching environment and to evaluate the competencies the students have developed concerning Lean and 5S processes and principles in relation to industry requirements.

This part of the summative evaluation serves multiple purposes. It gauges the practical application and sustainability of the training, observes any improvements in classroom efficiency, productivity, and student engagement, and determines the extent to which these changes are sustained over time. By doing so, it provides a comprehensive view of the course's effectiveness and informs future iterations. The feedback collected during these visits will play a critical role in guiding subsequent course offerings and may also influence broader CTE program development and industry partnership strategies.

Through a combination of qualitative and quantitative data, this two-part summative evaluation framework provides a holistic view of the educational impact of the course. It ensures that the objectives set forth at the outset are not only met initially but continue to resonate and bear fruit long after the course's conclusion.

Impact on Future Course Planning

The insights from these evaluations are vital in refining future iterations of the course. They identify strengths, uncover gaps, and verify the long-term viability of teaching strategies, influencing the course's content and instructional methods. This feedback is pivotal for maintaining the course's relevance and effectiveness.

Importance of Sharing Evaluation Findings

Sharing the outcomes of summative evaluations with stakeholders is crucial. The insights assist course facilitators and instructional designers in refining the curriculum and validating the effectiveness of the training to industry partners and school administrators. Plus, this information provides return on investment (ROI) information for industry leaders by providing hard data on if the course is meeting the goals and objectives set forth by these stakeholders. Also, educators benefit by receiving information that contributes to their professional growth and teaching practices, while helping to ensure that their high school students gain the required 5S Lean skills.

Conclusion

Evaluations transcend being mere endpoints; they are integral to the continuous evolution of the 5S Lean Manufacturing course. Bridging immediate feedback with long-term outcomes, these evaluations validate the instructional design's effectiveness and ensure the course remains a valuable asset to the educational and industrial sectors. The information gleaned shapes not only current teaching practices but also future course developments, ensuring that educators are well-equipped to meet both theoretical and practical demands to ensure these critical 5S Lean skills get passed down to the next generation of manufacturers.

Appendix A: Formative Evaluations

|  |

|---|

Appendix B: Summative Course Final Evaluations

|  |  |

|---|---|---|

|

CONTENT OUTLINE

An Instructor's Manual is used to provide an outline of the course content as well as detailed instructions for the setup and facilitating of the 5S Lean Manufacturing course.

The following components are included in the manual:

-

Course Overview

-

Goals and Objectives

-

Schedule

-

Agenda

-

Learning Materials

-

Activities, Assessments, and Evaluations

-

Course Facilitation

-

Course Preparation and Setup

-

Introduction and Course Overview

-

Understanding 5S Lean

-

Applying 5S Lean Principles and Practices

-

Manufacturing Factory Tour and Post Discussion

-

Implementing 5S Lean into CTE Classrooms

-

CTE and Industry 5S Lean Collaborations

-

Wrap-Up, Feedback, and Course Evaluation

ADDITIONAL RESOURCES & REFERENCES

-

AdLit. (2023). Anticipation guide template. Anticipation Guides. Retrieved March 20, 2024, from https://www.adlit.org/in-the-classroom/strategies/anticipation-guides

-

Al-Aomar, R. A. (2011). Applying 5s lean technology: An infrastructure for continuous process improvement. International Journal of Industrial and Manufacturing Engineering, 5(12), 1606-1611.

-

Anid, N. M. (2018). Educating the future advanced manufacturing workforce. Chemical Engineering Progress, 114(7), 38.

-

Barkley, E. F., & Major, C. H. (2016). Learning assessment techniques: A handbook for college faculty. Jossey-Bass.

-

Brown, A.H. & Green, T.D. (2020). The essentials of instructional design: Connecting fundamental principles with process and practice (4th Ed). New York, NY: Routledge.

-

Chandrayan, B., Solanki, A. K., & Sharma, R. (2019). Study of 5s lean technique: A review paper. International Journal of Productivity and Quality Management, 26(4), 469-491. https://doi.org/10.1504/ijpqm.2019.099625

-

Chaparro, R., Reaves, M., Jagger, C. B., & Bunch, J. C. (2021, August 19). Instructional design using the dick and carey systems approach. Askifas. https://edis.ifas.ufl.edu/publication/WC294

-

Difference between assessment and evaluation. Key Differences. (2017, October 21). https://keydifferences.com/difference-between-assessment-and-evaluation.html

-

Formsbirds.com. (2024). Index cards template. FormsBirds. https://www.formsbirds.com/download-index-cards-template

-

Kolb, A. Y., & Kolb, D. A. (2017). Experiential learning theory as a guide for experiential educators in higher education. Experiential Learning and Teaching in Higher Education, 1(1), 7-44. https://doi.org/10.46787/elthe.v1i1.3362

-

Patrick, K. (2020, October 14). What is the 5s methodology and how does it apply to lean six sigma and beyond? YouTube. https://www.youtube.com/watch?v=ddKVNOmrwkI&t=2s

-

Rizkya, I., Syahputri, K., Sari, R. M., & Siregar, I. (2019). 5s implementation in welding workshop – A lean tool in waste minimization. IOP Conference Series: Materials Science and Engineering, 505(1), 1–4. https://doi.org/10.1088/1757-899x/505/1/012018

-

Selko, A. (2021, July 26). The skilled labor shortage threatens manufacturing’s full recovery, says study. Industry Week. https://www.industryweek.com/talent/article/21169565/the-skilled-labor-shortage-threatens-manufacturing-sectors-fully-recovery-says-study.

-

Steele, C. (2020, October 14). The 5s methodology. GoSkills.com. Retrieved from https://www.goskills.com/Lean-Six-Sigma/Resources/5